|

The

HANIL

electric

heat

engineering

company

air

heater

is

designed

and

engineered

to

heat

a

flowing

air

or

gas

stream

under

accurately

controlled

conditions.

its

simplicity

od

design

makes

it

adaptable

for

most

production

and

test

applications.

A

standard

line

is

offered

for

voltages

up

to

220

volts

and

flows

above

1200

scfh.

they

are

available

for

used

both

in

oxidizing

and

non-oxidiizing

gases

in

either

open

or

nozzled

configurations.

The

air

heaters

type

1,2,3

are

a

family

of

simple

to

use,

extremely

compact

heaters.

A

ferrous

alloy

or

tungsten

heating

element,supported

by

a

ceramic

core,is

housed

in

a

quartz

or

ceramic

tube.

A

adaptor

with

spade

terminals,provides

the

means

for

making

air/innert

gas

hose

and

electrical

connections.

A

built-in

mounting

braket

makes

this

high

temperature

heater

easy

to

install

in

existing

or

new

equipment.

Standard

units

heat

air

ir

inert

gases

up

to

760

°C.

Inert

gas

temperatures

as

high

as

800

°C

can

be

achieved

using

our

tungsten

heater

elements.

|

![한일전열엔지니어링 에어히터[air heater]](a_img/AIR-1A.gif)

|

operating

media

of these

heaters

has

been

limited

to air,

forming

gases

and

highly

purified

inert

gases,

or inert

gases

containing

small

percentages

of reducting

gas,

prior

to using

any

other

input,

refer

to a

suitable

referance

of gaseous

effects

on materials

in order

to protect

against

heater

deterioration

and

failure

with

possible

injurious

results.

a

continuous

stream

of air

or gas

flows

in and

around

a serpentine

filament

mounted

on a

threaded

ceramic

core,

and

housed

in a

durable

quartz

or stainess

steel

tube.

the

winding

configuration

exposes

the

total

element

surface

tom

the

direct

flow

resultinh

in extremely

high

heat

transfer

properties

and

a thermal

efficiency

in excess

of 90%

is obtained.

A

adaptor

with

spade

terminals,

provides

the

means

for

making

air/innet

gas

hose

and

electrical

connections.

A built-in

mounting

bracket

makes

this

high

temperature

heater

easy

to install

in existing

or new

equipment.

Standard

units

heat

air

or inert

gases

up to

600°C.

Inert

gas

temperatures

as high

as 760°

Ccan

be achieved

using

our

tungsten

heaterelements.

If

you

require

a heater

not

listed

above,

contact

hanil

sales

engineer.

(1).

AIR

HEATER

APPLICATION

Plastics

:

Forming

and

welding

plastic,heat

shrinking

plastic

tubing

Semiconductor

: Soldering,lead

frames,capacitors,wafer

and

board

drying

Joing

:

Single

or mutiple

starion

soldering

operatings

Packaging

:

High

speed

poly

sealing,

compositr

can

manufacturing

Testiles

:Cutting/trimming

and

texturing

fibers,drying

cloth

Industry

drying

processes

: Curing

and

drying

resins,inks,lacquers

Sterilization

: Medical/surgical

hardware,packaging

materials

(2).

AIR

HEATER

OF

STOCK

LIST

![한일전열엔지니어링 에어히터[air heater]-표준규격](a_img/AIR-2A.gif)

|

PART

NUMBER

|

WATT

|

LENGTH

(L)

|

MAX.

FLOW

RATE

|

MAX.

TEMPERATURE

|

MAX.

PRESSURE

|

|

110V |

220V |

|

HAN-H-11 |

|

300W |

79mm |

2 L/Min |

600 °C |

2Kg/Cm² |

|

HAN-H-12 |

HAN-H-22 |

600W |

|

HAN-S-11 |

|

300W |

89mm |

2 L/Min |

600 °C |

2Kg/Cm² |

|

HAN-S-12 |

HAN-S-22 |

600W |

|

HAN-M-11 |

|

300W |

115mm |

2 L/Min |

600°C |

2Kg/Cm² |

|

HAN-M-12 |

HAN-M-22 |

600W |

|

HAN-M-13 |

HAN-M-23 |

800W |

150mm |

3

L/Min |

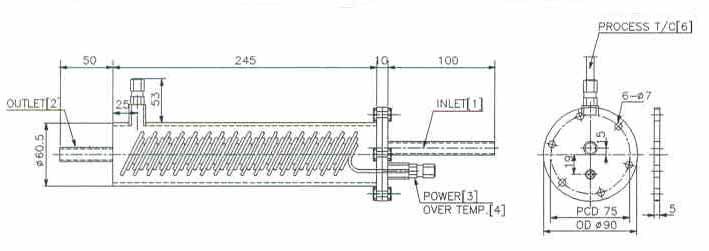

(3)

SEMICON

AIR

HEATER

OF STOCK

LIST

|

|

|

ORDERING INFORMATION

|

STAR |

- |

□□ |

- |

□□ |

- |

□□□ |

- |

□ |

- |

□ |

- |

□ |

|

|

|

- |

|

- |

|

- |

|

- |

|

- |

|

- |

|

|

|

1 |

|

2 |

|

3 |

|

4 |

|

5 |

|

6 |

Specify

: By Inlet(1/4"),Outlet(1/4"),

Wattage(220/1000W), Internal Thermocouple(J),

Surface

Finish(ELECTROPOLISHED),Process Thermocouple(J),And Special

Features If Required.

Example:

STAR-ET-ET-210-J-E-J |

|

|

|

|

1. INLET[A]

|

ET - OUTDIAMETER 1/4"(6.35mm)

PIPE |

|

JT - OUTDIAMETER 1/2"(12.70mm)

PIPE |

|

|

|

|

2. OUTLET[B]

|

ET - OUTDIAMETER 1/4"(6.35mm) PIPE |

|

JT - OUTDIAMETER 1/2"(12.70mm) PIPE |

|

|

|

|

|

3. HEATER

WATTAGE

|

105 - 110V/ 500 WATT |

205 - 220V/ 500 WATT |

|

107 - 110V/ 750 WATT |

207 - 220V/ 750 WATT |

|

110 - 110V/1000 WATT |

210 - 220V/1000 WATT |

|

115 - 110V/1500 WATT |

215 - 220V/1500 WATT |

|

120 - 110V/2000 WATT |

220 - 220V/2000 WATT |

|

|

|

|

4. INTERNAL THERMOCOUPLE

CALIBRATION [HEATER]

|

X - NONE |

|

J - TYPE"J" |

|

K - TYPE"K" |

|

|

|

|

5. SURFACE FINISH OF

ASSEMBLY & HEATER

|

X - NONE |

|

E - ELECTROCPOLISED |

|

|

|

|

6. PROCESS THERMOCOUPLE

CALIBRATION [ASSEMBLY] |

X - NONE |

|

J - TYPE"J"

|

|

K - TYPE"K" | |

|