Since the transportation is easy and the largest high tension saturated steam is used as the vinegar small size and ultra-light the effect is excellent and the steam temperature and pressure conditioning is possible and the manipulation is convenient and someone can use easily with the security.

if it goes down to the water level in which the water supply is fixed, it maintains by the automatically appropriate water level. As to pressure switch, on-going basis regulation is possible with the necessary pressure.

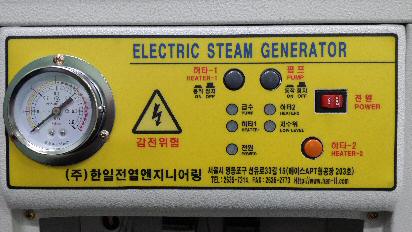

The steam generator is composed of the pressure gauge, level gauge, water pump, and sight glass and on/off control. and outlet in which the steam spouts is PT 1/2 ",PT 1" and PT 2" inlet PT 1/4" ,PT 1/2 ",PT 1".

The thermal efficiency is higher than the normal boiler. Because it is economic and the safety is excellent and it is not corroded, it extends the life of the instrument.

Every kind of safety device and gauge lamp was made with the miniaturization and the installation space was small to the utmost designed.

The safety break method was adopted among 3 and the safety was made and it designed so that the unattended operation could be possible.

The manufacture is possible in 2KW including the place consuming the steam which is every kind of research institute, hospital, computer room, Pilot Plants, and back intermittent and which it writes and industrial hot water boiler, steam boiler, and etc. to 300KW. And the assemble to order is possible in the special specification. 1. The installation basic data of ELECTRIC STEAM GENERATOR Parts name | The standing chi shot method | The heating

element

power Supply | Tighten firmly in the incomming axis terminal of the earth leakage breaker and connect the wire of the thickness in which it fits for the current capacity.

(if, if it is loosely the team, the heat is generated and the damage of the terminal can be caused) | Earth terminal | Certainly connect the earthing conductor of the thickness like the power supply cord. | Condensation water drainage | - the condensated water has to be cannot collect and drained.

- the water less than the 40¡É can be used as the steam generator water. | Operation

source Supply | In case of using the heating element power the grant 220, 380, and one 440V middle connect the power plug (the manipulation and feed pump power) to the separate power, that is the single phase 220V. | Steam outlet | Connect to the piping to the place where the steam is needed.

The pipe laying uses the steel pipe and by using the glass wool cover, it keeps warm. | The essence

drain | It is the inside sludge discharge work it connects the piping to the sinkhole easy. | Condensate

receiver tank | Since not collecting the condensated water, there is no need that it installs the separate tank. | The water inlet port | - Connect in Suwon more than the water pressure 1kg/§² (the chicken pox 1M).

- Wash the impurities of the inside of the water pipeline enough and finally, connect.

- The water used in the steam generator uses the use of waterwork as the rule. (the subsurface water for using installs the water softening apparatus and certainly has to use)

- The feedwater pipe is kept warm in order to prevent freezing and bursting.

- Connect the water supply pipe with the socket of the steam generator bottom left. (the water supply pipe is connected to the pull-in socket of the supplement water tank installed in the inside. And the plotting valve is set in order to maintain the premier position in about 2/3 considering water pressure. |

2. ELECTRIC STEAM GENERATOR standard Standard number | Stream amount | Electricity

Capacity | Power | NOZZLE | Pressure

(Kg/Cm²) | Dimension

[W x L x H] | INLET | OUTLET | HSG-003-2 | 4 Kg/hr | 3Kw | 220,1 PH | 1/2" | 1/4" | 3 - 4 | 460 X 670 X 760 | HSG-005-2 | 6 Kg/hr | 5Kw | 220,1 PH | 1/2" | 1/4" | 3 - 4.5 | HSG-010-2 | 13Kg/hr | 10KW | 220, 1 Ph | 1/2" | 1/4" | 3 - 4.5 | HSG-015-3 | 20 Kg/hr | 15Kw | 220, 3 Ph | 1/2" | 1/4" | 3 - 4.5 | HSG-015-4 | 20 Kg/hr | 15Kw | 380, 3 Ph | 1/2" | 1/4" | 3 - 4.5 | HSG-020-4 | 26 Kg/hr | 20Kw | 380, 3 Ph | 1/2" | 1/4" | 3 - 4.5 | 475 X 795 X 810 | HSG-025-4 | 33 Kg/hr | 25Kw | 380, 3 Ph | 1/2" | 1/4" | 3 - 4.5 | 475 X 795 X 960 | HSG-030-4 | 40 Kg/hr | 30Kw | 380, 3 Ph | 1/2" | 1/2" | 3 - 4.5 | HSG-040-5 | 53 Kg/hr | 40Kw | 380, 3 Ph | 1/2" | 1/2" | 3 - 4.5 | HSG-050-5 | 67 Kg/hr | 50Kw | 380, 3 Ph | 1/2" | 1/2" | 3 - 4.5 | HSG-060-5 | 80 Kg/hr | 60Kw | 440, 3 Ph | 1/2" | 1/2" | 3 - 4.5 | 480 X 750 X 1000 | HSG-070-5 | 94 Kg/hr | 70Kw | 380, 3 Ph | 1/2" | 1/2" | 3 - 4.5 | HSG-080-5 | 107 Kg/hr | 80Kw | 440, 3 Ph | 1/2" | 1/2" | 3 - 4.5 | HSG-100-4 | 134 Kg/hr | 100Kw | 380, 3 Ph | 1" | 1/2" | 3 - 5 | 1200 X 600 X 1000 | HSG-100-5 | 134 Kg/hr | 100Kw | 440, 3 Ph | 1" | 1 | 3 - 5 | 1200 X 600 X 1000 | HSG-130-5 | 156 Kg/hr | 130Kw | 380, 3 Ph | 1" | 1" | 3 - 5 | 1000 X 1350 X 1500 | HSG-130-5 | 156 Kg/hr | 130Kw | 440, 3 Ph | 1" | 1" | 3 - 5 | 1000 X 1350 X 1500 | HSG-150-5 | 180 Kg/hr | 150Kw | 440, 3 Ph | 1" | 1" | 3 - 5 | 1000 X 1350 X 1500 | HSG-180-5 | 210 Kg/hr | 180Kw | 440, 3 Ph | 1" | 1" | 3 - 5 | 1200 X 1350 X 1500 | HSG-200-5 | 240 Kg/hr | 200Kw | 440, 3 Ph | 1" | 1" | 3 - 5 | 1200 X 1350 X 1500 |

3.The steam generator operates under if all connections end.

¨ç

|

Turn on WATER of the cooling water line. [for using bib valve holds the faucet always]

|

¨è

|

the steam generator front cover is opened and it uploads and the cover the button of the

earth leakage breaker is closed in "ON" status.

|

¨é

|

Insert 220V control handling power of the steam generator front side right side in the socket.

|

¨ê

|

"ON" trains the power switch of the overall upper right side.

|

¨ë

|

Beat the pump button.

|

¨ì

|

after the operation of pump- If the heater-1 and heater-2 button is beat after 2 minutes, while the lamp is turned on, the operation starts.

|

|

* Principle: Because the operation begins by the steam tank of the steam generator inside in

the condition without the water if the heater-1 button is beat in advance, the heater is overheated

and the damage is generated.

The low-water level lamp is turned on in the early steam generator operation and this is inside the

steam generator the time that there is no water. And this lamp is put out soon.

At this time, since the electric capacity of the socket is insufficient if ON/OFF state is repeated,

the electrical wire or socket in which the capacity is big has to be used for the seen instrument.

|

¨í |

As to the steam generator, because of insufficiently being set up as 3.9Kg/Cm ², if 3.9Kg/Cm ² comes to the manometer, the heater operation is stopped. The heater is turned on if 1Kg/Cm ² comes to the manometer.

After 1 running accuracy releases the volt of the feed pump head stomach and the air is ejected, since if the air is cold inside the feed pump, it runs idle and is not watered it is the sleep gold tooth. |

¨î |

Insufficiently the steam is made with 20~ in 25 minutes. And if the steam production is completed,

3KW steam generator controls the ball valve according to the steam quantity which opens the ball

valve of the steam outlet and uses and uses.

The steam is made if the manometer indication indicates 3.9Kg/Cm ². At this time, the steam

production or no opens the valve of the steam outlet little by little. |

¨ï |

In the steam generator internal, the vacuum release valve of the steam generator ejects the internal pressure gradually. Do the role that it clears the ball. |

¨ð |

After the drain valve of the overall bottom right is opened if the operation of the steam generator is finished in the winter season, the cooling water is discharged.

Since the high-temperature water is ejected when draining the operation immediately after, it has to be careful about the burn.

Moreover, when the steam generator is not used for the winter season over the long time, the pump inside water is drained, and freezing and bursting of the pump can be prevented. |

¨ñ |

The order of the case that it stops the driving of the steam generator is the same under.

- Heater- Beat 1, 2 buttons.

- Beat the pump button.

- Beat the power switch by "OFF" status. Close the water feed water valve. |

¨ò |

Hope the inquiry detailed on content headquarters of a party. | |

![]()

![]()